The evolution of European emissions regulations is key to reducing European passenger vehicle (PCMO) and heavy-duty vehicle (HDDO) emission levels. To meet these challenging regulations, automakers have come up with advanced engine designs and sophisticated aftertreatment equipment. In addition, innovative lubrication technology helps to reduce emissions.

Emissions from driving a vehicle are any fumes expelled from the engine during operation. The main air quality pollutants emitted by gasoline and diesel engines are:

- carbon monoxide

- Nitrogen oxides (NOx)

- Unburned hydrocarbons

- Particulate Matter (PM)

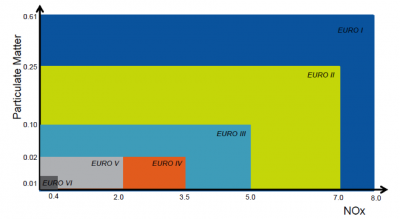

European emission regulations regulate the discharge of these pollutants. Regulated emissions levels have dropped by 98% since 1990, making Europe one of the most stringent emissions regulations.

Euro VI tightens HDDO emission limits

Euro VI standards for all new heavy duty diesel trucks were introduced in January 2014. Compared with the previous Euro 5 standard, Euro 6 has extremely strict restrictions and poses serious challenges to engine designers:

- 80% reduction in NOx levels to 0.4g/kWhNOx

- 50% reduction in PM to 0.01 g/kWh

Euro VI not only takes into account the weight of PM, but also the amount of particulate matter. In addition, the latest emission standards address the efficiency of exhaust gas aftertreatment devices.

Read more about Euro VI in the ICCT (International Council on Clean Transportation) Euro 6/VI vehicle emission standard technical summary.

30 years ago, one heavy-duty highway truck produced as much particulate matter as 100 heavy-duty premium vehicles produced today.

How Automakers and OEMs Can Reduce Emissions

To meet stringent emissions regulations, car and engine manufacturers propose a combination of solutions:

- Advanced engine technology including Common Rail and High Pressure Injection (CR), Variable Geometry Turbocharging (VGT), Exhaust Gas Recirculation (EGR) and high efficiency oil separator for Closed Crankcase Ventilation Circuit (CCV).

- Advanced aftertreatment system including Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF) and Selective Catalytic Reduction (SCR) with Ad Blue injection.

Diesel particulate filters are introduced to reduce particulate matter and meet Euro IV requirements. These devices remove diesel particulate matter or soot from diesel engine exhaust. To meet these standards, all new trucks are equipped with a DPF.

Many commercial vehicles also use a combination of selective catalytic reduction and urea additives to help reduce nitrogen oxide emissions. This technology alone can reduce NOx emissions by up to 90%.

How Innovative Lubricant Technology Can Help Reduce Emissions

The global quest to reduce emissions and improve fuel efficiency presents new challenges for OEMs. At Q8Oils, we develop innovative lubricant technologies that are helping to make huge strides in reducing emissions from passenger cars and heavy-duty vehicles.

Our low viscosity and HTHS lubricants support new engine technologies and improve fuel economy.