Emissions regulations are a hot topic in the automotive industry. To meet the latest Euro VI regulations, truck manufacturers are integrating aftertreatment devices (ATD) into their engines to limit emissions of harmful pollutants.

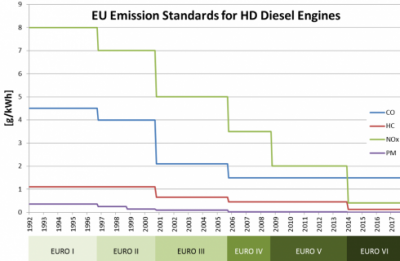

As a truck driver, you quickly become familiar with emissions regulations. The latest Euro VI emission regulations require heavy trucks to meet specific emission standards. This regulation applies to all motor vehicles with a technically permitted maximum load of more than 3.500 kg and with compression-ignition engines or positive-ignition natural gas (NG) or LPG engines. The Euro VI regulation introduced as Directive 88/77/EEC specifies maximum emission levels for CO, HC, NOx and PM (see table).

How Diesel Truck Engines Can Meet VI Regulations

To meet Euro VI emissions regulations, diesel truck manufacturers integrate aftertreatment devices (ATD) into their engines. These units replace traditional mufflers, allowing the truck to operate more efficiently while limiting emissions of gaseous pollutants. Aftertreatment equipment can consist of several systems:

- Diesel Oxidation Catalyst (DOC): Breaks down pollutants in the exhaust stream, converting them into less harmful compounds. When combined with Closed Crankcase Ventilation (CCV), DOC can reduce particulate matter by up to 40%.

- Selective Catalytic Reduction (SCR): An aftertreatment process in which urea is injected into the exhaust stream to chemically react with nitrous oxide to form a harmless substance. The SCR system reduces nitrous oxide by up to 90%.

- Exhaust Gas Recirculation (EGR): Reduces nitrous oxide when starting a cold engine and recirculates part of the exhaust flow to reduce nitrous oxide emissions from the engine. Combined with an SCR system to meet the most stringent nitrous oxide reduction standards.

- Diesel Particulate Filter (DPF): Removes particulate matter from diesel engine exhaust. Particles are reduced by up to 90% or more.

- Closed Crankcase Ventilation (CCV): Helps improve exhaust emission reductions by eliminating crankcase emissions. CCV eliminates up to 100% of crankcase emissions.

How does an aftertreatment device work?

The ATD uses regeneration to burn off the collected particulate matter. For successful regeneration, the exhaust gas must be kept at high temperature for a long time. If the temperature is not high enough, particulate matter can clog the diesel particulate filter. This phenomenon is also known as diesel particulate filter clogging.

Diesel engines produce nitrous oxide, a toxic air pollutant that poses a serious health risk to truck drivers. Selective catalytic reduction systems are added to aftertreatment units to reduce nitrous oxide levels. SCRs treat diesel exhaust with ammonia, causing a chemical reaction that converts nitrous oxide into harmless substances such as nitrogen and water vapor. The trucks use urea to produce ammonia (AdBlue consists of 32.5% urea and 67.5% deionized water).

HDM's Truck Diesel Engine Oils Help Meet Emissions Regulations

HDM's truck diesel engine oils have excellent flow characteristics that ensure the lubrication of critical engine components even under the harshest conditions. But they don't just protect your engine, they're also specifically designed to meet the latest and higher emissions standards.